Finding the right gear for your concrete construction gig can be a real pain in the neck. Mate, we’ve walked that rocky road too, uncovering that nearly 70% of knockbacks in construction are due to dodgy material quality.

Our deep dive into research has shed some light on the game-changing role of top-notch materials for building solutions that last ages. This yarn will take a squiz at how picking the cream of the crop for your next project can make it not just tougher and more eco-friendly, but also a sight for sore eyes.

Stick around for some fair dinkum revelations!

The Importance of High-Quality Materials in Concrete Construction

High-quality materials are essential in concrete construction for their durability, sustainability, and aesthetic appeal. These materials ensure that structures can withstand the test of time while minimising environmental impact and enhancing visual appeal.

Durability

We ensure our construction projects stand the test of time by focusing on durability. Choosing durable materials in modern concreting not only upholds the structural integrity but also reduces maintenance costs over a building’s lifespan.

Our approach aims to craft permanence through innovative construction techniques and high-quality materials, guaranteeing that every project we undertake is built to last.

Our commitment extends to integrating advanced construction techniques with sustainability at their core. This blend results in infrastructure that withstands various environmental conditions while supporting sustainable building practices.

We constantly seek out the latest developments in construction technology and materials science to enhance durability without compromising on aesthetic appeal or ecological responsibility.

Engaging these principles, each structure we create embodies resilience, ready to serve generations to come with minimal environmental impact.

Sustainability

Sustainability shapes the bedrock of modern concreting, pushing us to incorporate sustainable construction techniques in every project. We prioritise the use of durable materials that promise long-term structural integrity and minimal environmental impact, aligning with global sustainability goals.

Our commitment extends beyond the build phase, as we aim for structures that maintain their condition with minimal upkeep, ensuring a reduced carbon footprint throughout their lifecycle.

Embracing advanced construction techniques enables us to set new standards in sustainable building. By integrating innovative building methods and sustainable construction materials into our practices, we lead the way towards greener infrastructure without compromising on quality or aesthetics.

This approach not only benefits our planet but also sets a solid foundation for future advancements in construction technology.

Crafting permanence through innovation and sustainability.

Aesthetic appeal

High-quality materials in modern concreting elevate the aesthetic appeal of any construction project. We choose premium ingredients that ensure the final structure shines with an unmatched finish, making every building a showcase of innovative design and architectural brilliance.

This approach transforms concrete from a mere functional medium into a canvas for artistic expression.

Our commitment to excellence doesn’t stop at durability and sustainability; it extends to creating visually stunning infrastructures that stand out. Through advanced construction techniques, we craft buildings that are not just strong but also beautiful, blending seamlessly with their surroundings or making bold statements within the urban landscape.

This fusion of aesthetics and performance sets our projects apart in the competitive world of construction.

Technological Advances in Modern Concreting

Modern concreting has seen significant advancements through the implementation of layered manufacturing, building automation, and sustainable construction techniques. These technologies have revolutionised the industry by enhancing precision, reducing manual labour, and promoting eco-friendly practices in concrete fabrication.

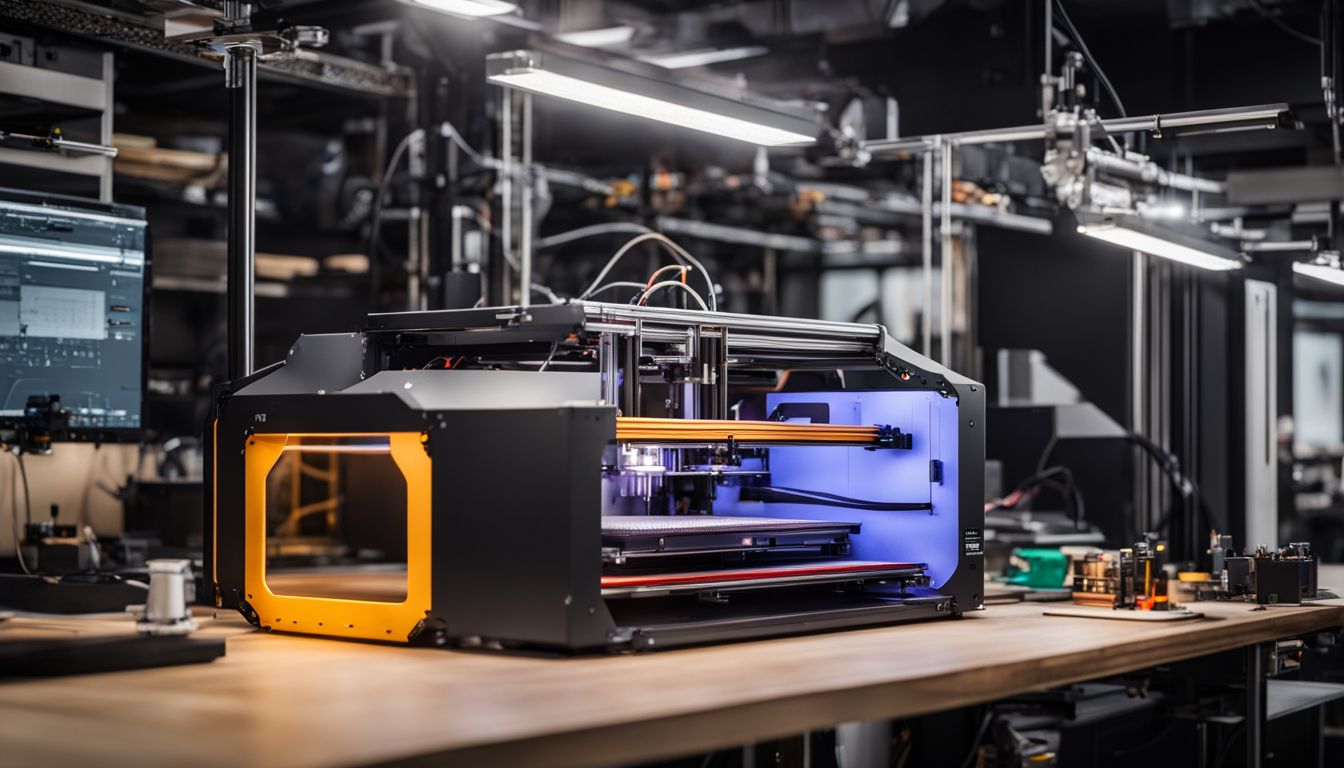

Layered Manufacturing

Layered manufacturing is revolutionising the way we approach construction projects, enabling precision and efficiency that traditional methods can’t match. This innovative construction technique involves building structures layer by layer using concrete fabrication.

It allows for more complex designs and shapes, pushing the boundaries of architecture and engineering. We harness this advanced method to create durable materials and sustainable building solutions, ensuring quality in every project.

This process stands out by drastically reducing waste and optimising material use. Our focus on sustainability drives us to adopt practices that not only benefit the present but also safeguard our future infrastructure needs.

Layered manufacturing represents a leap forward in automated construction techniques, marrying design innovation with environmental responsibility. Through careful planning and execution, we deliver projects that embody both strength and sustainability, setting new standards in the industry.

Building Automation

Building automation stands as a cornerstone of innovative construction techniques, transforming the way we manage and operate buildings. We harness advanced technology to automate various building systems, ensuring optimal performance in energy use, security, and environmental control.

This leap towards automated solutions promises not just efficiency but also significant savings in operational costs.

Automation is redefining the future of building design and management.

We integrate sensors and intelligent software into the very fabric of our construction projects. These smart systems allow for real-time monitoring and adjustments, leading to a more sustainable and user-friendly environment.

As we move forward, embracing these technologies marks a pivotal step in crafting buildings that are not only durable but adaptable to our changing needs.

Sustainable Construction Techniques

Moving from building automation, we shift our focus to sustainable construction techniques. These practices are reshaping how we approach projects, setting new standards in environmental responsibility and resource efficiency.

Our commitment lies in adopting methods that not only meet today’s building demands but also preserve the planet for future generations.

We integrate sustainable materials into our constructions, such as recycled steel and low-impact concrete, reducing the carbon footprint of each project. Green roofing systems and rainwater harvesting technologies are part of our blueprint for sustainable development.

These innovations offer a dual benefit: they enhance a building’s efficiency while protecting natural resources. As business owners, embracing these techniques can significantly impact your operational costs and brand image positively.

The Role of Contour Crafting in Construction

Contour crafting in construction improves project quality, increases speed and efficiency, and offers versatility in material use. To discover the full potential of this innovative method, delve into its applications and benefits.

Improved Project Quality

We focus on ensuring improved project quality through the incorporation of innovative construction materials and advanced construction techniques. Our approach leverages sustainable building practices, which not just meet but exceed industry standards.

By integrating building automation and layered manufacturing into our projects, we enhance durability, sustainability, and aesthetic appeal of constructions.

Our commitment to using high-quality materials in all our concrete fabrication efforts results in structures that withstand the test of time. We prioritise sustainability in our construction materials selection process, aiming for both environmental friendliness and superior performance.

This dedication to excellence across every aspect of our work ensures that each project remains a testament to innovation in modern concreting.

Speed and Efficiency

In modern concreting, the use of contour crafting technology significantly increases speed and efficiency in construction projects. This advanced technique allows for the rapid layer-by-layer fabrication of structures using high-quality materials.

By automating the building process, contour crafting minimises labour-intensive tasks and streamlines construction timelines, providing a practical solution to meet demanding project deadlines.

Moreover, this innovative method optimises material usage, reducing waste and ensuring efficient resource allocation throughout the construction phase. The versatile nature of contour crafting empowers builders to complete projects faster while maintaining exceptional quality standards.

With layered manufacturing techniques in place, businesses can expect enhanced operational productivity by expediting their construction processes without compromising on durability or structural integrity.

Versatility in Material Use

High-quality materials enable us to explore various material options, from traditional concrete to advanced compounds, composites, and recycled substances. This versatility allows for the creation of custom solutions tailored to specific project requirements whilst ensuring strength, sustainability, and aesthetic appeal.

The ability to adapt material composition unlocks the potential for innovative construction methods and designs that align with evolving industry needs. Embracing this flexibility not only enhances project outcomes but also fosters creativity and resilience in our construction practices.

Concrete Solutions: Maitland’s Answer to Next-Generation Building Needs

Concrete Solutions: Maitland’s Answer to Next-Generation Building Needs

Maitland offers innovative concrete solutions that meet next-generation building needs. Our advanced technologies and materials provide durable, sustainable, and aesthetically pleasing options for construction projects.

These high-quality solutions are tailored to the complexities of modern construction, offering versatility in material use and enhancing project quality.

Business owners can benefit from Maitland’s automated construction techniques and formwork systems, which reduce costs and increase efficiency. Our approach not only addresses current industry demands but also prepares for the ever-evolving world of construction technology.

With Maitland’s concrete solutions, businesses can unlock the secrets to successful, robust, and sustainable building projects.

The Impact of Automated Construction on the Industry

Automated construction has revolutionised the industry by streamlining processes and increasing efficiency. Innovative technologies have reduced costs, improved precision, and accelerated project timelines, driving a wave of transformation in modern construction practices.

Innovation

Innovation in construction has revolutionised the industry, spearheading advanced techniques and technologies that have reshaped traditional building methods. Layered manufacturing, building automation, and sustainable construction techniques represent just a few of the groundbreaking advancements driving change in the way we construct our infrastructure.

These innovations not only streamline processes but also enhance project quality while significantly reducing costs, making them imperative for business owners seeking to stay ahead in an ever-evolving realm.

The utilisation of high-quality materials combined with innovative building methods underscores a commitment to sustainability and efficiency, catering to the growing demands of modern construction projects.

Contour crafting technology is another notable innovation that has gained traction within the industry. This cutting-edge approach offers improved project quality, speed and efficiency, as well as versatility in material use – providing business owners with adaptable solutions tailored towards their specific needs.

Reduced Costs

To streamline construction expenses, we implement automated processes and utilise sustainable building materials. By leveraging building automation and layered manufacturing, we significantly reduce operational costs while maintaining high-quality standards.

Our strategic use of advanced construction techniques not only enhances project efficiency but also minimises overall expenditure on labour and resources. These practices enable us to offer cost-effective solutions without compromising on the durability or aesthetic appeal of our projects.

Moving beyond reduced costs, let’s explore the next area: “Concrete Solutions: Maitland’s Answer to Next-Generation Building Needs.”

Conclusion

Crafting Permanence: The Role of High-Quality Materials in Modern Concreting is crucial in addressing the durability and sustainability of construction projects. Technological advances enable layered manufacturing, building automation, and sustainable construction techniques to improve project quality.

Contour crafting not only enhances speed and efficiency but also offers versatility in material use. Maitland’s innovative concrete solutions answer next-generation building needs, impacting the industry with reduced costs and automated construction innovation.