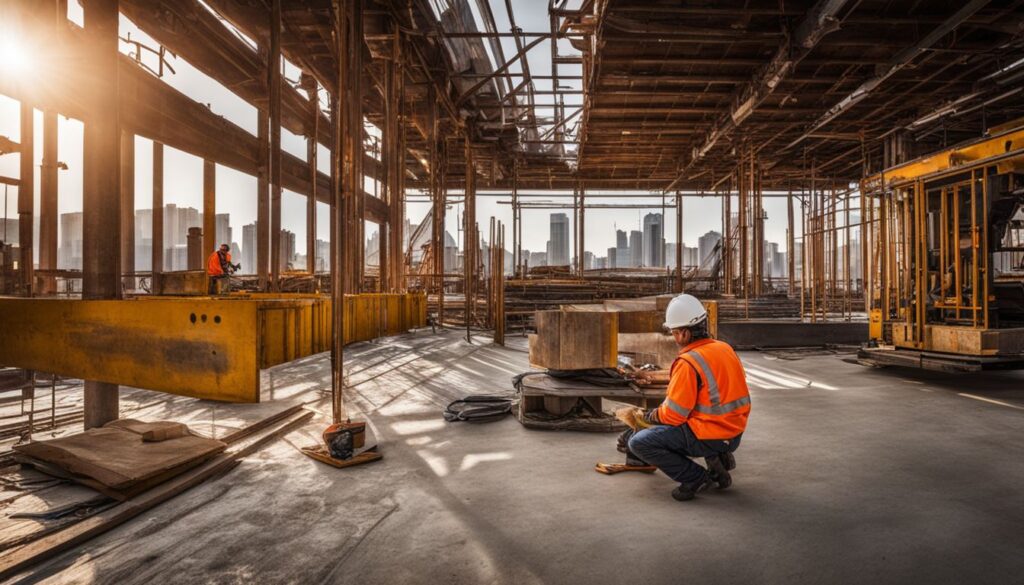

Building quality construction kicks off with a solid base, no worries. We’ve clocked the challenges and fully understand the importance of nailing it from the get-go, particularly after finding out formwork systems can chew up to 60% of the total cost in concrete structures.

Our yarn today shines a spotlight on top-notch formwork systems as your go-to solution. Buckle up and get ready to find out why this is a game changer.

Understanding Formwork Engineering

Formwork engineering plays a crucial role in construction projects by creating temporary structures for concrete moulding. It ensures the integrity and quality of reinforced concrete, offering tailored solutions to meet specific project requirements.

Definition and Role in Construction Projects

Formwork plays a pivotal role in construction projects, setting the stage for building integrity and architectural expression. It acts as a temporary mould where concrete is poured and allowed to harden, creating the structures that become the backbone of our buildings.

By shaping reinforced concrete, formwork systems determine the size, shape, and surface texture of these essential elements.

Construction formwork transforms engineering visions into tangible realities.

We craft these systems from various materials like timber, plywood, aluminium, and steel to meet diverse construction needs. Each choice impacts project timelines, budgeting strategies, and overall quality improvement in construction outcomes.

Our expertise guides business owners and homeowners through selecting the ideal formwork solution that aligns with their project goals while ensuring safety compliance in this critical phase of construction engineering.

Types of Formwork Systems

When it comes to formwork systems, they encompass a range of types such as timber, plywood, metallic, plastic, and fabric formwork that cater to various construction needs. Read more for deeper insights into the world of formwork engineering.

Timber, Plywood, Metallic, Plastic, and Fabric Formwork

We use a variety of materials for formwork in construction projects, including timber, plywood, metallic, plastic, and fabric. Each type has its own advantages that can make or break the efficiency and cost-effectiveness of a build.

Timber and plywood are widely praised for their versatility and ease of cutting into various shapes, making them ideal for unique architectural features. Metallic formwork, often made from steel or aluminium, offers exceptional strength and durability; it’s perfect for large scale structures demanding high levels of stability.

Plastic and fabric formworks present innovative solutions to construction challenges. Plastic forms are lightweight yet sturdy, reducing labour intensity while ensuring quality concrete moulding.

Fabric formwork stands out for its ability to create more complex shapes with fewer seams than traditional materials allow. This broad range ensures we can meet diverse building integrity requirements across the construction industry.

Moving on to understand how selecting the right kind of formwork impacts project success is crucial for any business owner or homeowner looking into undertaking a construction venture.

The Impact of Choosing the Right Formwork

Selecting the right formwork is crucial for ensuring quality construction and building integrity. It directly influences the safety, speed, and cost effectiveness of a project. With various options available, from timber to aluminium formwork systems, each type offers distinct advantages depending on the specific requirements of your build.

Making an informed choice can significantly reduce potential structural issues and enhance the overall durability of your structure.

Our expertise in construction engineering helps us guide you through choosing the optimal formwork system that aligns with your project goals. Knowing which material—be it plywood, metallic, plastic or fabric—best suits your construction needs not only ensures a smoother building process but also impacts long-term maintenance costs and sustainability objectives.

The cornerstone of quality construction lies in expert formwork systems; selecting wisely lays a solid foundation for any successful build.

Tailored Formwork Solutions: Where Detail Meets Durability

We understand that each construction project is unique, needing special consideration for the finest details to ensure building integrity and quality. Our custom formwork solutions cater exactly to these needs, blending detail with durability in every design.

We craft formwork that aligns perfectly with your specific architectural requirements, supporting structures from foundations to facades with unmatched strength and precision.

Our team applies expert knowledge in construction engineering and utilises high-quality construction materials, including aluminium formwork systems, to create solutions that not only meet but exceed expectations.

This approach ensures every project benefits from a foundation robust enough to withstand future challenges while maintaining the aesthetics of the build. With our help, businessowners and homeowners can rest assured their projects stand on solid ground, combining aesthetic appeal with structural soundness for long-lasting results.

Innovative Solutions and Safety Compliance in Formwork Engineering

In the field of formwork engineering, we’re constantly pushing the boundaries to integrate innovative solutions that ensure both efficiency and safety. Our focus on cutting-edge technology allows us to design systems that are not only faster to assemble but safer for workers at all stages of construction.

We prioritise incorporating lightweight materials and intelligent design elements, such as aluminium formwork systems, which offer superior strength while minimising risks on site.

Safety compliance forms the backbone of our operations. Every piece of formwork equipment we deploy meets stringent safety standards because protecting our teams is paramount. We conduct regular inspections and training sessions to keep everyone abreast of best practices in handling construction materials and navigating through complex structural challenges with ease.

This commitment ensures our projects embody quality construction from ground up, setting a solid foundation for enduring structures.

Next, let’s explore how these principles impact overall building integrity.

Conclusion

Expert formwork systems stand as the backbone for quality construction. These systems shape buildings, ensuring strength and durability from the ground up. By choosing the right type of formwork, projects gain both practicality and efficiency.

Embracing innovative solutions enhances safety and meets industry standards. Let’s build with confidence, knowing our structures rest on solid foundations.